Table of Contents

Context: Rubber farmers from Kerala, Tripura, Tamil Nadu, and Karnataka, that are affiliated to the All-India Kisan Sabha (AIKS), have demanded a fair remunerative price (FRP) of at least ₹300 for a kilogram of natural rubber.

Rubber Industry in India

Characteristic Features of Rubber:

- Natural rubber is a polymer of isoprene, an organic compound.

- Rubber is a coherent elastic solid obtained from the latex of tropical trees of which Hevea brasiliensis is the most important.

- Rubber is a native of the Amazon basin and was introduced to countries in the tropical belts of Asia and Africa in the late nineteenth century.

- Rubber trees have an economic life period of around 32 years in plantations.

Sources of Rubber:

-

- Natural rubber comes from various sources, the most common being the Pará rubber tree (Hevea brasiliensis). It grows well under cultivation and yields latex for several years.

- The vines in the genus Landolphia yield the Congo rubber. These vines cannot be grown in cultivation and this led to large-scale exploitation of the wild plants in Congo.

- Latex is also present in dandelion milk which can be used to produce rubber.

Cultivation of Rubber Trees:

- Soil:

- The trees demand well-drained and well-weathered soils.

- Lateritic type, alluvial, sedimentary types, and non-lateritic red soils are best for the growth of these trees.

- Precipitation and Temperature:

- An evenly distributed rainfall with at least 100 rainy days a year and a temperature range of about 20 to 34°C are optimum conditions for the growth of the Hevea rubber tree.

- A humidity of around 80%, 2000 hours of sunshine, and absence of strong winds are also necessary for the best results.

Uses:

- Rubber is used for several purposes from erasing pencil marks to manufacturing tyres, tubes and a large number of industrial products.

- Natural rubber is preferred over synthetic rubber due to its high tensile strength and vibration dampening properties, along with tear resistance.

- This makes it important for the construction and automobile industries.

- The growth of the automobile market across countries is anticipated to increase the demand for natural rubber production.

- The rise in demand for latex products, such as catheters, gloves, and belts, is also a factor that is likely to aid in the growth of the rubber market.

Production and Distribution

State of Rubber Production in India:

- India is one of the world’s significant producers of natural rubber.

- According to FAOStat (Food and Agricultural Organisation Corporate Statistical Database) of 2019, Thailand is the largest Producer of Rubber in the World followed by Indonesia, Malaysia, India, China etc.

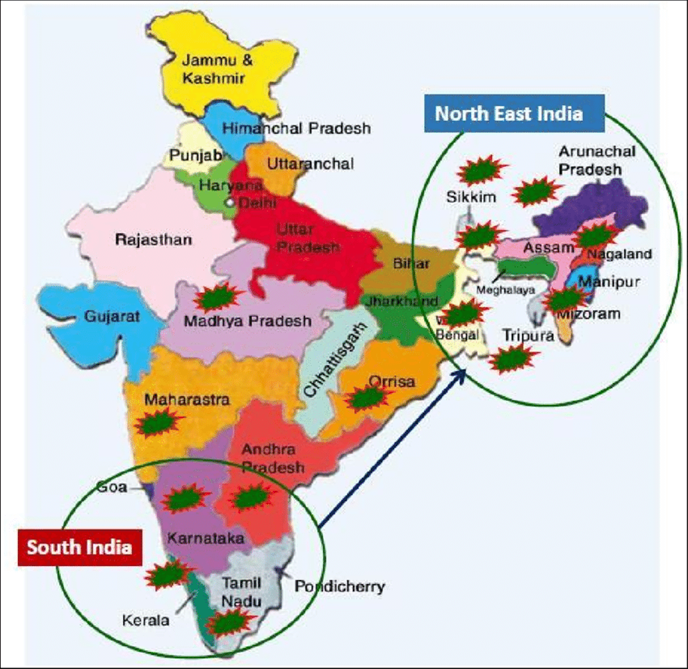

- Kerala is the largest rubber-producing state in India, and it plays a crucial role in the country’s rubber industry.

- Major areas: Kottayam, Kollam, Ernakulam, Kozhikode districts produce practically all the rubber of this state.

- Other key rubber-producing states in India include Tamil Nadu (Nilgiri, Madurai, Kanniyakumari, Coimbatore and Salem), Karnataka (Chikmagalur and Kodagu), Tripura, Assam, Andaman & Nicobar, Goa, and others.

- The rubber industry in India consists of approximately 6,000 units, including large, medium, and small-scale units.

Exports and Imports

- Exports:

- India exports natural rubber to various countries, with Germany, Brazil, the United States, and Italy being some of the top importers of Indian natural rubber.

- Export products include automobile tires and tubes, footwear, pharmaceutical goods, hoses, coats, and aprons.

- The quantity of natural rubber exported from India for the fiscal year 2020 was reported to be above 12,000 metric tonnes.

- Imports:

- India’s imports of rubber primarily consist of products like Ribbed Smoked Sheets (RSS).

- India is said to import approximately 50,000 tonnes of rubber every year.

Challenges Faced by the Rubber Industry in India

- High Labour Costs: Labour-intensive activities like tapping rubber trees require skilled workers, and paying for labour amid falling prices has made rubber cultivation economically challenging.

- Import Competition: The influx of cheaper imported rubber puts pressure on domestic prices and discourages domestic production.

- Climate Change: Changing weather patterns influenced by climate change pose challenges to rubber farming, particularly in traditional cultivation areas like Kerala.

- Lack of Technological Adoption: Limited adoption of technological advancements in the industry hampers productivity and competitiveness.

- Land Conversion and Fragmentation: Instead of finding ways to increase production, some rubber plantations are being sold or converted for other purposes, leading to the fragmentation of rubber holdings.

- Conflict of Interests: Conflicting interests between rubber growers and tire companies have contributed to market challenges and demand fluctuations.

Government’s initiatives in the Rubber sector

- Rubber Plantation Development Scheme: To support the development of rubber plantations by providing financial assistance to farmers.

- Rubber Group Planting Scheme: Financial incentive by the government to form rubber farmer groups and societies.

- National Rubber Policy 2019: It includes provisions to support the natural rubber production sector and the entire rubber industry value chain.

- Sustainable and Inclusive Development of the Natural Rubber Sector (Implemented by the Rubber Board) for R&D in the rubber plantation.

- 100% Foreign Direct Investment (FDI) in Rubber Plantations is allowed.

Institutions related to Rubber Industry

Rubber Board

- The Rubber Board is a statutory organization constituted under Section (4) of the Rubber Act, 1947 and functions under the administrative control of Ministry of Commerce and Industry.

- Headquarters: Kottayam, Kerala.

- Composition: The Board is headed by a Chairman appointed by the Central Government and has 28 members representing various interests of natural rubber industry.

- Functions:

- The Board is responsible for the development of the rubber industry in the country by way of assisting and encouraging research, development, extension and training activities related to rubber.

- It also maintains statistical data of rubber, takes steps to promote marketing of rubber and undertake labour welfare activities.

AIRIA (All India Rubber Industries Association):

The All-India Rubber Industries Association (AIRIA) is a not for profit making body serving the rubber industry and trade with the objectives of safeguarding and promoting interests of the industry.

Way Forward

- Promote Research and Development: Establish dedicated research institutes and laboratories focused on advancing the field of rubber production. These institutions should prioritize the development of new rubber varieties, improved cultivation techniques, and solutions to address the challenges posed by climate change.

- Genetically Modified (GM) Rubber: The Rubber Board research farm is currently cultivating the world’s first genetically modified (GM) rubber plants tailored to thrive in the specific climatic conditions of Northeast India.

- Encourage Technology Adoption: Promote the widespread adoption of modern farming technologies, such as rubber-tapping machines and automation, to enhance efficiency and reduce labour costs in rubber cultivation.

- Enhance Financial Support and Subsidies: Provide financial assistance, subsidies, and accessible loans to support rubber farmers in establishing plantations, replanting, and embracing modern cultivation practices.

- Improve Infrastructure and Logistics: Establish dedicated rubber clusters and industrial parks to create a conducive ecosystem for the rubber industry, including improved infrastructure and logistics.

- Focus on Skill Development: Collaborate with educational institutions and vocational training centers to empower individuals with the necessary skills and knowledge for successful rubber cultivation.

- Strengthen Market Connections: Encourage partnerships between rubber farmers and industries that rely on rubber-based products, such as the tire manufacturing sector. These partnerships will help ensure a steady demand for rubber products and fair pricing.

- Promotion of Rubber in India’s Northeast: In collaboration with the Rubber Board, four members of the ATMA have an ambitious plan to establish 200,000 hectares of new rubber plantations in Northeast India and West Bengal, promoting rubber cultivation in these regions.

Future of Governance in Post-Maoist Indi...

Future of Governance in Post-Maoist Indi...

Sabka Bima Sabki Raksha Amendment Bill 2...

Sabka Bima Sabki Raksha Amendment Bill 2...

MP Police Answer Key 2025 Out at esb.mp....

MP Police Answer Key 2025 Out at esb.mp....