Table of Contents

Context: The Indian Prime Minister laid the foundation of the Green Hydrogen Hub (GHH) under the National Green Hydrogen Mission, at Pudimadaka in Anakapalli district, near Visakhapatnam.

About Green Hydrogen

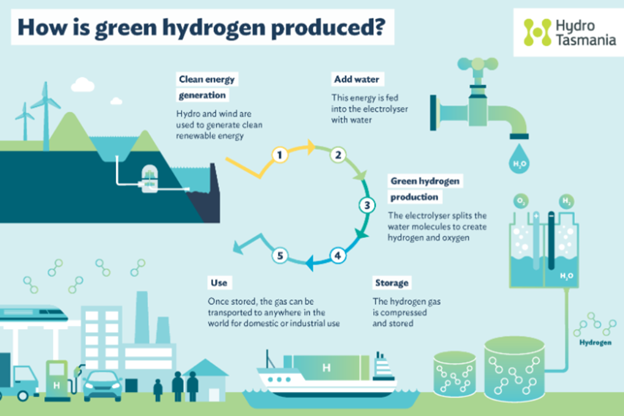

Green hydrogen is produced by renewable energy through the electrolysis of water. Electrolyser technology is central to the green hydrogen production process. Electrolysis involves the splitting of water (H2O) into its constituent elements, hydrogen (H2) and oxygen (O2), using an electric current.

Commercially available technologies for Green Hydrogen Production

- Alkaline Electrolyzers: Alkaline electrolyzers operate via the transport of hydroxide ions (OH-) through the electrolyte from the cathode to the anode with hydrogen being generated on the cathode side.

- Polymer Electrolyte Membrane Electrolysers: In a polymer electrolyte membrane (PEM) electrolyser, the electrolyte is a solid speciality plastic material.

- Solid Oxide Electrolysers: It uses a solid ceramic material as the electrolyte that selectively conducts negatively charged oxygen ions (O2-) at elevated temperatures (700°–800°C) to generate hydrogen.

Applications

Green hydrogen can be consumed through direct combustion, electricity generation through fuel cells and industrial processes like ammonia, steel manufacturing and petroleum refinery to be used as chemical feedstock.

| Hydrogen |

| • Hydrogen is a colourless, odourless, flammable gaseous substance, and it is the most abundant element in the universe. • It has the potential to substitute conventional fuels and reduce CO2 emissions. • Hydrogen energy has the highest energy content by weight, and it has the lowest energy content by volume. |

Green Vs. Grey Hydrogen

| Aspect | Green Hydrogen | Grey Hydrogen |

| Definition | Hydrogen gas is produced through the electrolysis of water using renewable energy sources, without carbon emissions. | Produced by steam methane reforming of natural gas, resulting in hydrogen and CO2 as byproducts. |

| Production | Utilises renewable energy (wind, solar, hydroelectric) for electrolysis, ensuring a carbon-neutral process. | Involves heating natural gas with steam and a catalyst, an energy-intensive process that emits CO2. |

| Environmental Impact | Environmentally friendly due to zero carbon emissions during production. | Less environmentally friendly due to significant CO2 emissions during production. |

| Use Cases | Used as a clean energy carrier for transportation, power generation, and industrial processes requiring hydrogen. | Used in refining petroleum, treating metals, producing fertilizers, and as a feedstock in various industrial processes. |

Types of Hydrogen

- Grey Hydrogen is traditionally produced from methane (CH4), split with steam into carbon dioxide (CO2, Green House Gas) and hydrogen.

- Grey hydrogen is increasingly being produced from coal, with significantly higher CO2 emissions per unit of hydrogen produced.

- It has no energy transition value.

- Blue Hydrogen follows the same process as grey. However, the CO2 produced is captured and stored for the long term through suitable technology.

- It is not possible to capture 100% of the CO2 produced and not all means of storing it are equally effective in the long term.

- Turquoise Hydrogen is made using a process called methane pyrolysis to produce hydrogen and solid carbon. In the future, turquoise hydrogen may be valued as a low-emission hydrogen.

- Green Hydrogen is defined as hydrogen produced by splitting water into hydrogen and oxygen using renewable electricity.

Why Green Hydrogen for Transportation?

- Reduces emissions to combat climate change.

- Curbs pollution and helps meet India’s climate goals.

- Reduces reliance on costly fossil fuel imports.

- Potential for India to become a global hub for green hydrogen production and export.

Advantages of Green Hydrogen as a Fuel

- High Calorific Value: Hydrogen has almost 2.5 times the energy per tonne compared to natural gas, shifting to Hydrogen thereby reduces natural gas imports.

- Energy efficiency: A hydrogen fuel cell is two to three times more efficient than a gas-fueled internal combustion engine.

- Climate change mitigation: The method of producing green hydrogen does not emit any greenhouse gases, helping in our fight against climate change.

- Also, Green hydrogen can potentially replace coal and coke in iron and steel production. Decarbonizing this sector will significantly impact India’s climate goals.

- Hydrogen can be effectively used as a fuel for heavy-duty vehicles, helping in the decarbonization of the transportation sector

- Storage: Hydrogen has the highest energy per mass of any fuel, which means that the higher a system’s energy density, the greater the amount of energy it can store.

- Cost effective: India’s distinct advantage in low-cost renewable electricity means that green hydrogen will emerge as the most cost-effective form.

- Grid stability: The intermittent nature of renewable energy, especially wind, leads to grid instability. But green hydrogen can be stored for long periods which can be used to produce electricity using fuel cells.

- Monetary benefits: Experts say the oxygen produced as a by-product can also be monetized by using it for industrial and medical applications or for enriching the environment.

- Demand: It is expected that Hydrogen demand in India could grow more than fourfold by 2050, representing almost 10% of global demand of which the majority of this demand could be met with green hydrogen.

Challenges Associated with Green Hydrogen Production in India

- Economic Viability: High production and electrolyzer costs make green hydrogen less competitive than traditional hydrogen.

- Eg., Green Hydrogen: Costs between $5.30 – $6.70 per kg.

- Grey/Blue Hydrogen: Much lower at $1.9 – $2.4 per kg.

- The significant price gap makes green hydrogen uncompetitive.

- Eg., Green Hydrogen: Costs between $5.30 – $6.70 per kg.

- Financing: The high weighted average cost of capital (WACC) and the lack of innovative financing models increase investment risks.

- Eg., An increase in WACC from 10% to 20% could lead to a 73% increase in the levelized cost of hydrogen, even if all other production factors remain constant.

- Infrastructure: Absence of the production, storage, and distribution of green hydrogen, including pipelines and refuelling stations.

- Policy Gaps: Limited focus on comprehensive policies and regulatory support.

- Demand Certainty: Industries lack confidence in future demand for green hydrogen.

- Eg., Only 27.6% of global clean hydrogen projects have reached final investment decisions.

- This indicates structural barriers to investment beyond technological readiness.

- Eg., Only 27.6% of global clean hydrogen projects have reached final investment decisions.

| WACC |

| WACC represents the average rate of return a company is expected to pay to all its shareholders, including both debt holders and equity investors, to finance its assets. |

India and Green Hydrogen

- Achieve Net Zero Emissions: India is the third-largest emitter of carbon dioxide (CO2) globally. The adoption of Green Hydrogen will facilitate India’s goal of lowering its carbon footprint and attaining net zero emissions by 2070.

- Decarbonization: Carbon-free hydrogen will enable substantial decarbonization in industries that produce iron ore and steel, fertilizers, methanol, refining and emit significant volumes of carbon dioxide (CO2).

- Self Sufficiency: India’s energy landscape is at a crucial turning point, and green hydrogen will have an essential role in making the country self-sufficient by 2047 and energy independent.

- Less Imports: Presently, India spends more than US$ 160 billion in foreign exchange every year for energy imports. A comprehensive action plan for establishing a Green Hydrogen economy can make India a hub for the production and export of green hydrogen.

Which Sectors in India Can Benefit from Green Hydrogen?

- Green Steel: In the coming years, green hydrogen-based steel will be cost-competitive due to the declining costs of renewable energy and electrolysers. Market restrictions on carbon-intensive steel and the provision of carbon credits will further increase the sustainability of steel made from green hydrogen.

- Transport: Hydrogen fuel is used to power fuel-cell electric cars which emit no hazardous gases. In the coming years, hydrogen fuel cell electric cars may become cost-competitive for heavy-duty vehicles with longer trip ranges, such as buses, lorries, and other commercial vehicles.

- Shipping: By using green hydrogens or their derivatives, such as green ammonia and green methanol, as fuel for propulsion and other operations, maritime transportation and ports have a significant potential to reduce their carbon footprint.

What Steps have been Taken to Promote Green Hydrogen in India?

National Green Hydrogen Mission

It has been approved with an initial outlay of Rs.19,744 crore. The Ministry of New and Renewable Energy (MNRE) will be responsible for overall coordination and implementation of the Mission. The components of the Mission are:

- SIGHT Programme: Under the Strategic Interventions for Green Hydrogen Transition Programme (SIGHT), two distinct financial incentive mechanisms – targeting domestic manufacturing of electrolysers and production of Green Hydrogen will be provided under the Mission.

- Pilot projects: The Mission will also support pilot projects in emerging end-use sectors and production pathways. Regions capable of supporting large-scale production and/or utilization of Hydrogen will be identified and developed as Green Hydrogen Hubs.

- R&D Projects: The Mission will assist the Strategic Hydrogen Innovation Partnership (SHIP), a public-private partnership structure for research and development. The objectives, deadlines, and magnitude of R&D initiatives shall be appropriate for creating globally competitive technology.

- Skill Development: A coordinated skill development programme will also be undertaken under the Mission.

Mission Benefits

- Development of green hydrogen production capacity of at least 5 MMT (Million Metric Tonne) per annum with an associated renewable energy capacity addition of about 125 GW in the country.

- Making India a leading producer and supplier of Green Hydrogen in the world.

- Creation of export opportunities for Green Hydrogen and its derivatives.

- Reduction in dependence on imported fossil fuels and feedstock.

- Attracting investment and business opportunities for the industry.

- Creating opportunities for employment and economic development.

Green Hydrogen/Green Ammonia Policy

The Government launched this policy to provide clean fuel to the common people of India. This will reduce dependence on fossil fuels and also reduce crude oil imports. According to the policy:

- Green Hydrogen / Ammonia manufacturers may purchase renewable power from the power exchange.

- Waiver of inter-state transmission charges for 25 years will be allowed to the manufacturers of Green Hydrogen and Green Ammonia for the projects commissioned before 30th June 2025.

Initiatives by States/PSUs

- Kerala Hydrogen Economy Mission: Kerala aspires to become a 100% renewable energy-based State by 2040 and net carbon neutral by 2050. The Government of Kerela has constituted the Kerala Hydrogen Economy Mission to contribute strategic inputs and facilitate partnerships towards transforming the State into a green hydrogen hub.

- Kerala is also the first State in India to include hydrogen-powered mobility in its zero emissions mobility policy.

- Indian Oil Corporation Ltd (IOCL): As part of a decarbonization effort, IOCL aims to replace at least a tenth of the present fossil fuel-based hydrogen at its refineries with green hydrogen.

- Oil & Natural Gas Corporation (ONGC): India’s state-run Oil & Natural Gas Corporation (ONGC) and joint venture partner Greenko signed an agreement in July 2022 to invest up to US$ 6.2 billion in green hydrogen and renewable energy projects.

Way Forward

- Strengthening Domestic Manufacturing – Setting up local electrolyser manufacturing facilities and developing hydrogen-related technologies will help reduce costs and enhance self-reliance in the green hydrogen sector.

- Enhancing Policy and Regulatory Framework – Simplifying approval processes, implementing clear land-use policies, and offering export incentives can attract investments and expedite green hydrogen projects.

- Promoting Public-Private Partnerships – Strengthening collaboration between the government, industries, and research

institutions can drive innovation and scale up hydrogen production. - Investing in Research and Development – Increased R&D funding for the development of cost-efficient electrolysers and advanced storage solutions will enhance the economic feasibility of green hydrogen.

- International Collaboration-Strengthening global partnerships, such as the India-EU collaboration on green hydrogen, can accelerate technology sharing, innovation, and investment.

Establishing localized industrial clusters connected to renewable energy sources can create self-sustaining hydrogen corridors.

| Global Policy Models for Green Hydrogen Development |

|

Comprehensive Policy Framework

Beyond production incentives, India needs policies addressing financing barriers.

- Strategies:

- Long-Term Hydrogen Purchase Agreements

- Partial Loan Guarantees to reduce uncertainty for investors.

- Regulatory Sandboxes for experimentation with new business models, similar to fintech innovation in India.

Innovative Financing Models

Move beyond traditional project finance to cater to hydrogen’s unique challenges.

- Financing Approaches:

- Modular Project Financing: Facilities scale in phases, reducing upfront capital needs.

- Anchor-Plus Financing: Base capacity underwritten by a creditworthy anchor customer, with flexible financing for additional capacity.

- Equipment Leasing: Transform electrolyzer costs into manageable operational expenses, following models used in solar and wind sectors.

International Collaboration

Move beyond aspirational agreements to practical market-making initiatives.

- Standardized Certification: For carbon intensity and hydrogen origin to facilitate exports.

- Eg., The Hydrogen Energy Supply Chain Project between Australia and Japan demonstrates how cross-border partnerships can secure demand certainty for large-scale investments.

Early projects in industrial hubs such as Odisha, Maharashtra, and Gujarat will be crucial in demonstrating viable business models for green hydrogen production.

Bioluminescent Beaches - Kavaru

Bioluminescent Beaches - Kavaru

Malabar Grey Hornbill, Characteristics a...

Malabar Grey Hornbill, Characteristics a...

Salt Pan Land Cleared for Dharavi Redeve...

Salt Pan Land Cleared for Dharavi Redeve...