Table of Contents

Context: In 2015, India’s Environment Ministry mandated all 537 coal-fired plants to install FGD systems by 2018 to curb SO₂ emissions. Due to various challenges, the deadline has been extended to 2027-2029.

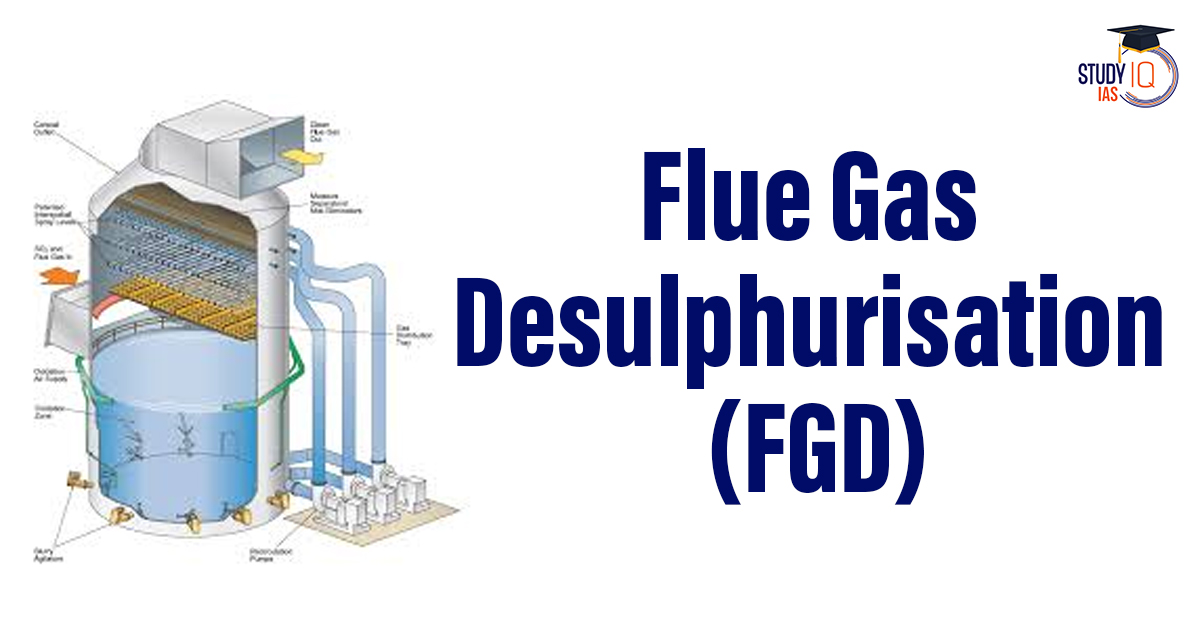

About Flue Gas Desulphurisation (FGD)

- Flue Gas Desulphurisation (FGD) refers to a set of technologies designed to remove sulfur dioxide (SO₂) from the exhaust flue gases of fossil-fuel power plants and other industrial processes.

- The primary goal is to reduce SO₂ emissions, which contribute to acid rain and respiratory problems.

- It uses various methods such as Wet Scrubbing, Dry Scrubbing, etc.

Advantages of FGD

- It can remove up to 90% or more of SO₂ from flue gases.

- The gypsum (byproduct) produced can be used in the construction industry, reducing waste.

- It helps power plants meet stringent environmental regulations regarding SO₂ emissions.

Challenge

- FGD systems are capital-intensive, with significant maintenance requirements.

- Wet FGD systems require excess water, which can be a concern in water-scarce regions.

Key Findings of the NIAS Study

The Office of the Principal Scientific Adviser, along with the National Institute of Advanced Studies (NIAS), Bengaluru, recently commissioned a study.

Findings of the Study

- 92% of coal used in Indian plants has low sulfur content (0.3%-0.5%), reducing the necessity for Flue Gas Desulphurisation (FGD).

- Only 8% of plants have installed FGDs, with 230 in various stages of installation and 260 yet to place orders.

- FGD installation costs are estimated at ₹1.2 crore per MW

Recommendations

- Flue Gas Desulphurisation (FGD) installation should be limited to plants using imported coal or coal with sulfur content above 0.5%.

- The focus should shift to controlling particulate matter (PM) emissions, which are detrimental to air quality in India.

- Electrostatic precipitators, costing ₹25 lakh per MW, can reduce PM pollution by 99% and are more cost-effective than FGDs.

De-extinction of Dire Wolf: Is the Once-...

De-extinction of Dire Wolf: Is the Once-...

International Big Cat Alliance (IBCA), O...

International Big Cat Alliance (IBCA), O...

Sanitary Waste Management Model of Karad...

Sanitary Waste Management Model of Karad...