Table of Contents

The Importance of Containers

- Containers are essential for transporting goods efficiently via rail, ship, and road, making them vital to global trade.

- The introduction of containerisation revolutionised trade by reducing transportation time and port delays, facilitating globalisation.

- Standardised in size and cargo capacity, containers allow goods to move over long distances without being disturbed, streamlining the supply chain.

India’s Current Container Scenario

- Increased Focus on Container Trade: India has increased container handling capacity at its ports to boost exports, with major projects like the Vadhavan and Galathea Bay ports and the India Middle East Europe Economic Corridor centred around container trade.

- The country’s container market is expected to grow significantly from 4 million TEU (Twenty-Foot Equivalent Unit) in 2023 to 26.6 million TEU by 2028.

- Insufficient Container Production: India manufactures only 10,000 to 30,000 containers annually, far short of the projected demand for rapid trade growth.

- In contrast, China produces 2.5 to 3 million containers per year, dominating global container manufacturing.

- The cost of producing a container in India is $3,500 to $4,800, while in China, the cost is $2,500 to $3,500. This price difference forces India to lease containers, mostly from China.

- Consequences of Shortage: Freight rates often increase due to container shortages, contributing to congestion at Indian ports.

- Despite India’s strategic location on the East-West trade route, Indian ports are unable to compete as hub ports. Ports in Colombo, Dubai, and Hong Kong attract mother ship traffic, while Indian ports depend on short-distance feeder vessels, increasing tariffs for Indian shippers.

- External Factors Affecting Container Availability: West Asia’s crises and disruptions in the Suez Canal can delay voyages by 10 to 15 days, further affecting container availability.

- The Russia-Ukraine war has closed ports, altered routes, increased insurance costs, and raised container freight rates.

- Piracy also inflates freight costs, adding to the logistical burden.

Government Measures and Recommendations

- Current Initiatives: The government has introduced Make in India initiatives to promote local production of containers, either through Public-Private Partnerships (PPP) or by incentivizing private manufacturers.

- Support measures like direct subsidies and viability gap funding are being explored.

- Suggested Measures for Improvement: Reducing charges for repositioning and storing empty containers would help ease the shortage.

- Increasing container yard capacities at Indian ports would promote trade and reduce congestion.

- Scaling up production is crucial, but it must be done in a way that brings costs down to global levels.

- The implementation of Production Linked Incentives (PLI), which has been discussed but not fully executed, would further support domestic container manufacturing.

- Raw Material and Production Incentives: Reducing GST on raw materials used for container production would lower input costs, making Indian containers more competitive.

- Offering incentives to Indian shippers using Indian-made containers and promoting long-term contracts between shippers and manufacturers would boost market confidence.

- Mandating the use of Indian-made containers would increase domestic demand and encourage the growth of the container production sector.

- Tracking and Logistics Platforms: Developing a tracking and tracing mechanism for containers through the Unified Logistics Interface Platform and Logistics Data Bank can reduce the turnaround time for export containers, further alleviating shortages.

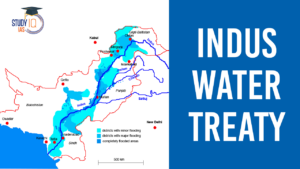

Indus Water Treaty 1960 Suspended by Ind...

Indus Water Treaty 1960 Suspended by Ind...

5 Years of SVAMITVA Scheme and Its Benef...

5 Years of SVAMITVA Scheme and Its Benef...

Places in News for UPSC 2025 for Prelims...

Places in News for UPSC 2025 for Prelims...