Table of Contents

Context: A U.K.-based start-up has recently claimed to have developed biotransformation technology that can alter the state of plastics and make them biodegradable without leaving behind any microplastics.

Understanding Biotransformation Technology

- Biotransformation technology is a process of altering the structure of plastic material to make it biodegradable.

- This means that it can break down naturally into harmless substances when exposed to the environment.

- With this technology, plastics are designed to have a specific time frame during which they function like conventional plastics, without compromising quality.

- Once that time frame ends and the plastic is exposed to the environment, it starts to self-destruct and transform into bioavailable wax, which can be consumed by microorganisms.

- The biotransformation process results in the conversion of plastic waste into water, CO2, and biomass, with no harmful microplastics left behind.

- This technology is considered a breakthrough in the effort to reduce plastic pollution and promote sustainability.

Need for such Technology

- According to the United Nations Environment Program (UNEP), around the world, around one million plastic bottles are purchased every minute, while up to five trillion plastic bags are used worldwide every year.

- In 2019, plastic packaging waste from e-commerce firms was estimated at over a billion kilograms worldwide, according to Statista.

- Also, according to recent reports, E-commerce giant Amazon generated an estimated 321 million kilograms (709 million pounds) of plastic from packaging waste in 2021 alone as a result of billions of boxes it shipped to its customers globally.

- As per the Ministry of Environment, India is generating 3.5 billion kgs of plastic waste annually and that the per capita plastic waste generation has doubled in the past five years.

- Of this, one-third comes from packaging waste.

- A joint research project by the Department of Management Studies, IIT Delhi, and Sea Movement noted that Amazon generated, nearly 210 million kgs (465 million pounds) of plastic from packaging waste in 2019.

- They also estimated that up to 10 million kgs (22.44 million pounds) of Amazon’s plastic packaging ended up in the world’s freshwater and marine ecosystems as pollution in the same year.

- With utility and waste discharge at such a large scale, alternate techniques for effectively and efficiently processing plastics is the need of the hour.

Types of Biotransformation Technology

In Which Sectors can this Technology be used?

Food packaging and health care industries are the two prime sectors that could use this technology to reduce waste. Apart from this, It can be employed in:

- Agriculture: Plastic mulch films are extensively used in agriculture to conserve moisture and control weed growth. However, these films are non-biodegradable and contribute to plastic waste generation. Biotransformation technology can be used to develop biodegradable mulch films, reducing the environmental impact of plastic waste in the agriculture sector.

- Textile industry: Synthetic textiles like polyester and nylon are widely used in the textile industry and are a significant contributor to plastic waste. Biotransformation technology can be used to develop biodegradable textiles that can break down naturally, reducing the environmental impact of plastic waste in the textile industry.

- Automotive industry: The automotive industry is a significant consumer of plastic products, including plastic components and packaging materials. Biotransformation technology can be used to develop biodegradable plastic components and packaging materials, reducing the environmental impact of plastic waste in the automotive industry.

- Construction industry: Plastic products like PVC pipes and sheets are widely used in the construction industry and are a significant contributor to plastic waste. Biotransformation technology can be used to develop biodegradable plastic products for the construction industry, reducing the environmental impact of plastic waste.

Limitations of Biotransformation

While biotransformation technology offers many advantages, there are also some limitations to its use:

- Substrate specificity: Biocatalysts are often highly specific, which means that they may only be able to transform certain types of substrates. This can limit the range of compounds that can be transformed using biotransformation technology.

- Process optimization: Biotransformation processes can be sensitive to process conditions, such as pH, temperature, and substrate concentration. Optimizing these conditions can be time-consuming and costly.

- Scale-up challenges: Scaling up biotransformation processes from the laboratory to industrial production can be challenging. This is due to the complex nature of biological systems, which can be difficult to control and optimize on a large scale.

- Enzyme stability: Enzymes used in biotransformation processes can be sensitive to changes in temperature, pH, and other process conditions. This can lead to reduced activity and lower yields.

- Cost: The cost of biotransformation processes can be higher than traditional chemical processes due to the need for specialized equipment and expertise.

- Time: Biocatalytic reactions may take longer than traditional chemical reactions, which can limit their use in some industrial applications where rapid reaction times are required.

Other steps taken by India to Reduce Plastic Waste

- Ban on single-use plastics: The Indian government has implemented a ban on single-use plastics, including items like polythene bags, straws, and cutlery. The ban is aimed at reducing the consumption of these items and promoting the use of sustainable alternatives.

- Swachh Bharat Abhiyan: The Swachh Bharat Abhiyan (Clean India Mission) was launched in 2014 to promote cleanliness and proper waste management in the country. The initiative includes a focus on plastic waste management, with an aim to reduce plastic waste generation and promote recycling.

- Extended Producer Responsibility: The Indian government has implemented Extended Producer Responsibility (EPR) regulations, which require producers to be responsible for the entire lifecycle of their products, including their disposal. This has encouraged producers to reduce plastic waste generation and promote recycling.

- Plastic Waste Management Rules: The Plastic Waste Management Rules, 2016, were introduced to regulate the management of plastic waste in the country. The rules require waste generators to segregate plastic waste at source and promote the recycling of plastic waste.

- Promotion of alternatives: The Indian government has promoted the use of sustainable alternatives to plastic, such as jute bags, cloth bags, and paper bags. The government has also encouraged the use of biodegradable plastics as an alternative to conventional plastic products.

World Population Day 2025, Themes, Histo...

World Population Day 2025, Themes, Histo...

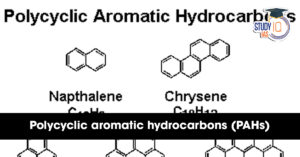

What are Polycyclic Aromatic Hydrocarbon...

What are Polycyclic Aromatic Hydrocarbon...

Marlin Fish: Species, Features, Appearan...

Marlin Fish: Species, Features, Appearan...