Table of Contents

Context: India’s first BioCNG gas station is located on the Deesa-Tharad highway in Dama village, Banaskantha district, Gujarat.

Case Study: Sustainable Energy and Agriculture Integration in Gujarat, India

Background

- In Gujarat, India, a groundbreaking initiative has transformed cattle and buffalo dung into a valuable resource, showcasing an innovative approach to sustainable energy production and agricultural enhancement.

- The Banaskantha District Co-operative Milk Producers’ Union launched India’s first BioCNG outlet based on cattle and buffalo dung, setting a precedent for renewable energy and bio-fertilizer production.

BioCNG Gas Station

- Location: The BioCNG outlet is situated on the Deesa-Tharad highway in Dama village, Banaskantha district, catering to 90-100 vehicles daily.

- Capacity: The plant sells 550-600 kg of BioCNG per day, produced from 40 tonnes of dung.

- Source: Dung is collected from 2,700-2,800 animals across five villages, contributing to the daily operation of the plant.

We’re now on WhatsApp. Click to Join

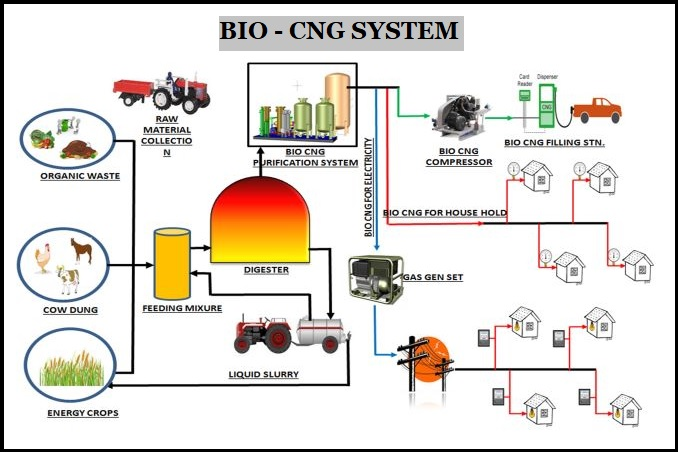

Process and Technology

- Biogas Production: Fresh dung undergoes anaerobic digestion in a 3,000 cubic metre digester, producing biogas containing 55-60% methane, CO2, and traces of hydrogen sulphide.

- Anaerobic digestion is a process by which the complex organic matter in dung is broken down in the absence of oxygen to produce biogas.

- The digestion involves four successive stages:

- Hydrolysis (break-down of organic matter into simple molecules),

- Acidogenesis (their conversion into volatile fatty acids),

- Acetogenesis (production of acetic acid, CO2 and hydrogen) and

- Methanogenesis (biogas generation).

- Purification: The raw gas is purified for removing CO2 (through vacuum pressure swing adsorption or VPSA process), H2S (using activated carbon filter) and moisture (with air dryer separator).

- End-Product: The end-product, purified (to 96-97% methane, 2-3% CO2 and below 0.1% H2S and moisture) and compressed, is stored in cascades.

- This compressed biogas (CBG), conveyed through pipelines to the dispensers at the fuel station, is what’s being sold as BioCNG at Rs 72/kg.

Economic and Environmental Impact

- Fuel and Fertilizer: The project not only provides renewable fuel but also produces bio-fertilizer, generating significant income from the sale of both products.

- Investment and Expansion: Initiated with an Rs 8 crore investment, the project plans expansion with four more plants by 2025, supported by a Rs 230 crore investment from Suzuki Motor Corporation.

- Farmers’ Benefit: Farmers receive Rs 1/kg for the dung and benefit from the sale of bio-fertilizers, enhancing their income and promoting sustainable farming practices.

Alternative Model in Anand District

- Decentralised Biogas Solution: Jagrutiben Padhiyar, a dairy farmer at Mujkuva village in Gujarat’s Anand district, utilises a 2 cubic metre Flexi Biogas plant to convert dung into biogas for cooking, eliminating her dependency on LPG.

- Community Impact: The success of decentralised biogas plants led by the Kaira District Co-operative Milk Producers Union demonstrates a scalable model for rural energy independence and economic growth.

About Bio CNG

- Purification Process: Bio-CNG is created by purifying biogas, achieving a methane purity level of 95%.

- Composition and Energy Potential: Bio-CNG composition and energy output closely match that of commercially available natural gas, with a calorific value of approximately 52,000 KJ/Kg.

- By-Product Utilisation: The residue from the Bio-CNG production process is transformed into high-quality concentrated liquid fertilizer.

- CO2 Capture and Utilisation: During the methane and CO2 separation process, CO2 is captured and packaged in cylinders, producing food-grade CO2 through a partnership with a leading European company.

- Financial Viability: The production of Bio-CNG is financially viable, offering multiple streams of revenue from the sale of Bio-CNG, food-grade CO2, and both liquid and solid organic fertilizers.

- Raw material sources of Bio-CNG:

- Agri-Waste including rice straw

- Municipal Sludge

- Press Mud

- Food Waste

- Spent wash of Distillery,etc.

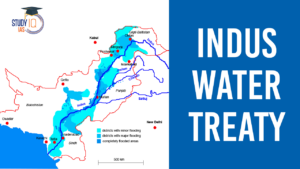

Indus Water Treaty 1960 Suspended by Ind...

Indus Water Treaty 1960 Suspended by Ind...

5 Years of SVAMITVA Scheme and Its Benef...

5 Years of SVAMITVA Scheme and Its Benef...

Places in News for UPSC 2025 for Prelims...

Places in News for UPSC 2025 for Prelims...